It could easily have never happened.

Lincolnshire Poacher cheese, based at F W Read and Sons farm in the Lincolnshire Wolds, is now a household name with an ardent army of fans who adore its unique tang.

But if it wasn’t for Simon Jones, the fourth generation of his family on the farm, exploring the possibility of turning the delicious milk his family’s dairy herd produced into cheese – based on an idea handed down from his grandfather to his father – then it wouldn’t have seen the light of day.

Simon’s slick, modern day operation is a direct result of his father Richard - a maverick architect from Essex with a passion for farming - stepping into the unknown.

Read more: Final call for growers to claim EU Levy Refund

“My dad was the one who came and injected a bit of madness into the business. He put dairy cows onto the Lincolnshire Wolds so all the local farmers thought he was a nutter!” said Simon.

“His rationale for that was to run a good farm you needed break crops. The best break crop in the late 1950s and early 60s was grass and best way at that time to utilise that grass was via dairy cows. That was his logic.”

But that was as far as it went for years until a disillusioned Simon returned to the dairy farm in 1988, struggling to see how he would fit in to the well-run set up.

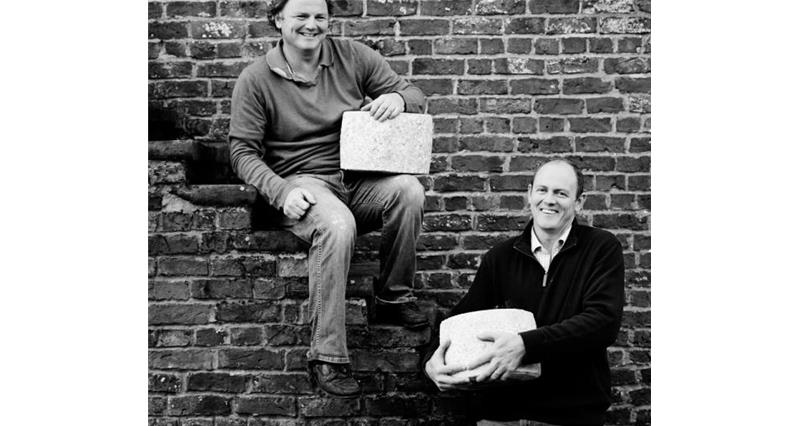

Brothers Simon (left) and Tim Jones run the operation

Finding work on a number of cheese making farms and enrolling on a course into the arcane skill, Simon returned to the Wolds armed with the knowledge he needed to begin.

Roping in help from Welsh cheesemaker Dougal Campbell and starting with a 1,000-litre vat, Simon made the first batch of Lincolnshire Poacher, based on Dougal’s Tyn Gryg cheese, on 17 February 1992.

“We were making 100 kilos of it once a week at the start. But then it all changed in 1996,” he said.

Read more: Westminster joins NFU to celebrate Back British Farming

Lincolnshire Poacher, the new kid on the block and just four years since its modest start, won the coveted supreme champion gong at the British Cheese Awards.

By then it had reached cult status at farmers’ markets around the area – and the local cheese shop even had to start rationing customers to a quarter of a pound each.

Now with experienced cheesemaker Richard Tagg working on the increasingly popular product, Lincolnshire Poacher’s presence expanded, with Simon’s brother Tim joining the business in 2000 in a marketing role.

“It was a different style – it’s not Cheddar,” said Simon.

More than 200 Holstein Fresians produce the milk for Lincolnshire Poacher

“It’s a cross between Cheddar and comte. It’s a raw milk cheese and delicious. And that’s the bottom line; if you make something delicious then people will want to buy it.”

Milk from the 230-strong Holstein Fresian herd is now almost exclusively used for cheese making, with a small amount sold in its raw state and the whey cream used for butter.

The original farm building has been converted and is the hub of the business, with a cheese dairy at one end, cutting room at the other and an office in the middle.

The loose-housed cows are milked twice a day and the milk, still warm, is pumped through a pipe over the farmyard and straight into the vat.

Read more: How the NFU is working for you

The environment is also central to production and on-farm activity.

500mwh of electricity – more than the farm consumes – is generated thanks to a wind turbine and solar panels. A straw pellet boiler is used for heating the milk, fuelled by straw baled at the farm, and a ground source heat pump warms the office and cutting room.

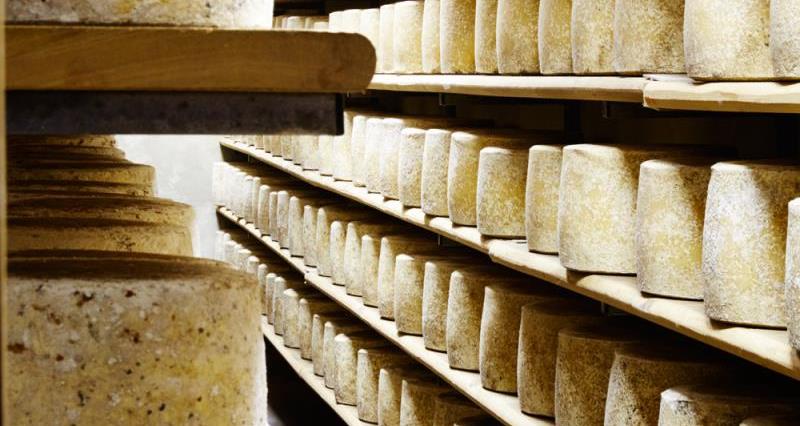

And unusual plans are afoot to future-proof the vital cheese turning part of the process with a robot, provisionally dubbed Florence the Flipper.

“You have to change all your racking to vertical and the robot moves up and down, moves the cheese into its body, turns it round, brushes it if you want, and puts it back,” Simon explained.

(L-R) LNR county adviser Harriet Ranson, East Midlands regional director Gordon Corner and Lincolnshire Poacher’s Simon Jones

“We’ve got 200 tonnes of cheese; 14,000 cheeses that need turning every month and our chap is 62 and meticulous in doing it. But finding somebody in this day and age when the time comes who’s going to want to physically lift those out, turn them over and put them back, is not going to happen.”

Lincolnshire Poacher is one of the most mature cheeses produced in the UK. The youngest cheese goes out at 16 months and oldest at three years.

The not-for-the-faint-hearted, three-year-old Knuckle Duster is only sold in one batch a year and is strictly under the counter for those in the know.

All products are Lincolnshire Poacher at different ages and seasons. The milk changes through the seasons, offering different fat and protein percentages from summer to winter.

To find out more, visit: www.lincolnshirepoachercheese.com